Our Quality Profile

We provide precision turned and milled components and assemblies in a wide range of ferrous and non-ferrous materials for the Aerospace, Defence, Automotive, Petrochemical and Research Industries both in the UK and Internationally.

Quality Assurance Approvals

Quickedge Ltd has in place a Quality Management System which is designed to comply with the requirements of ISO 9002

Quality Documentation Available:

1. Letter of Conformity

For those items stocked and supplied outside our QA system.

2. Certificate of Conformity

For in-house manufactured and inspected items.

3. EN 10204 31B Certification

For material used during in-house manufacturing.

Quality System

Quickedge Ltd's Quality Policy and response to the requirements of BSEN ISO 9002 registration is documented in manual form, issued to its customers on a request and acknowledgement basis. This top tier manual is supported by detailed quality procedures.

Contract Review

All customer contracts are reviewed for their completeness and the ability of Quickedge Ltd to meet all requirements.

Document Control

Procedures exist to ensure that all specifications, drawings and control documents are maintained at current issue status and that obsolete items are removed promptly from the point of use.

Purchasing

Only those suppliers listed in the Authorised Supplier list, controlled by the Administration department, are used for the procurement of any raw materials and process assistance which may have an effect on product quality.

Traceability

All product batches are traceable throughout manufacture and release by the use of unique batch numbering systems. Where required, traceability of incoming materials can be demonstrated by the use of a unique Quickedge Material Number.

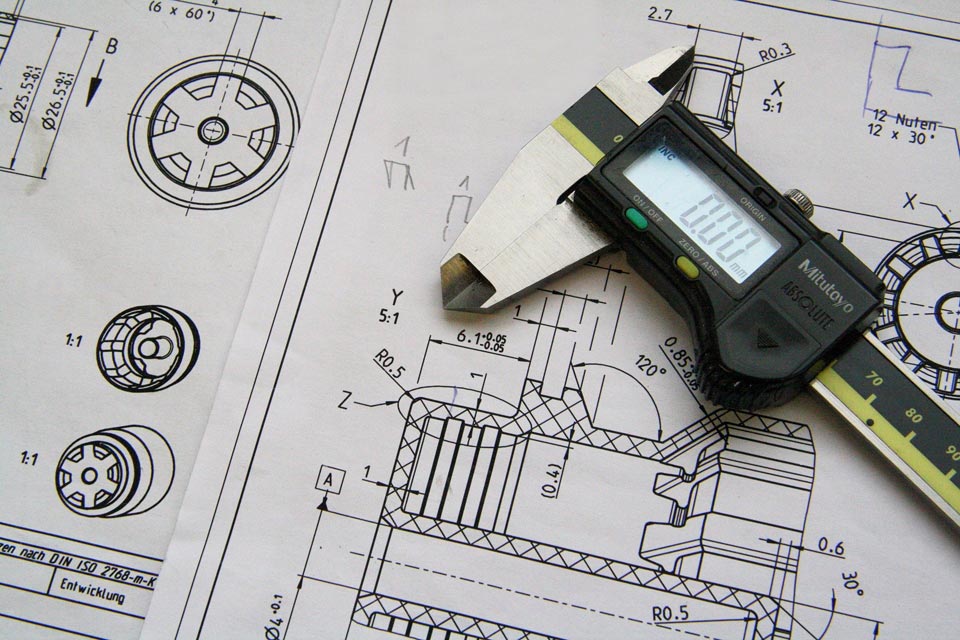

Inspection and Testing

Inspection and testing in accordance with documented procedures is carried out to ensure the quality of supplied goods, in process quality and the quality of finished items prior to despatch.

Calibration

All measuring, test and process control equipment is maintained in a state of known calibration using control devices traceable to national standards.

Inspection Status

Inspection status is apparent at all times by the use of quality signatures and conformance labels.

Non-Conformance and Corrective Action

Any non-conformances over an agreed level are segregated, quarantined and investigated. All investigations are documented and any resultant corrective actions are monitored for effectiveness.

Handling and Storage

All products supplied by Quickedge Ltd are handled in a manner which ensures product quality, by the use of dedicated equipment, packing and controlled storage conditions

Records

Records that demonstrate the achievement or specification of quality levels are maintained for a minimum of five years unless otherwise agreed with customers.

Training

Regular reviews of the training and development needs of all employees are carried out, documented and implemented.